Research and development

Our work has always been centered on research and development.

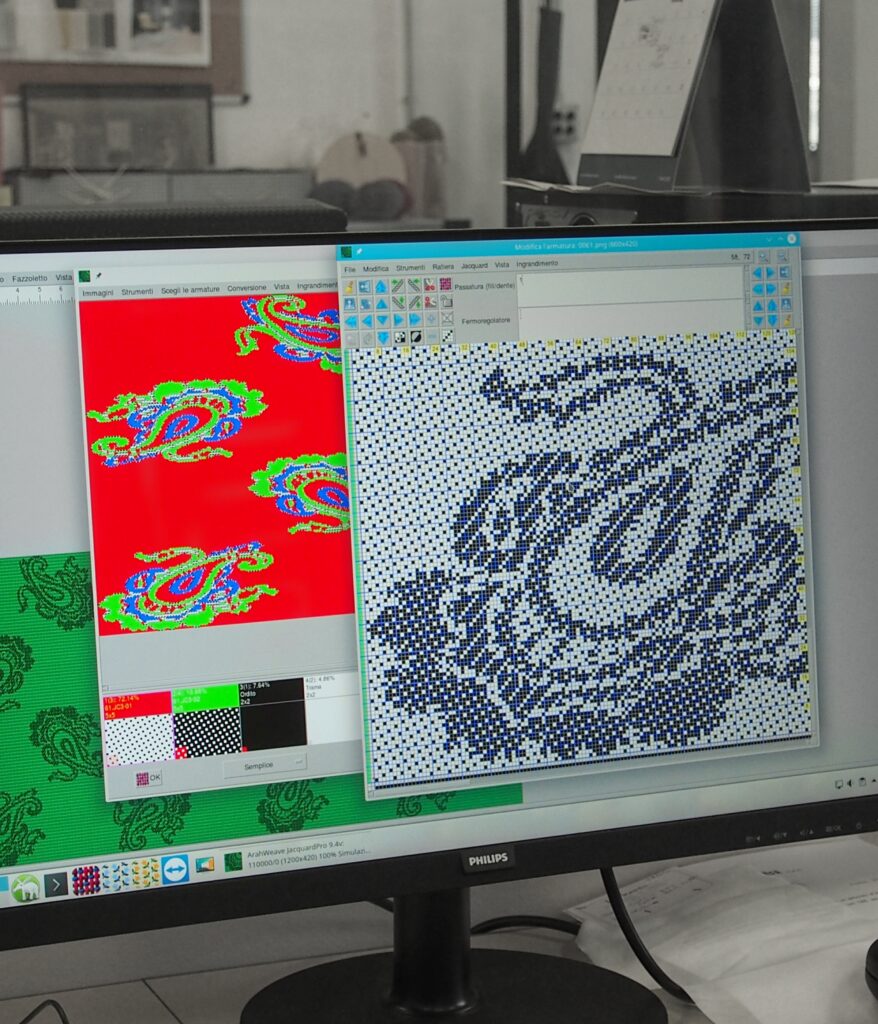

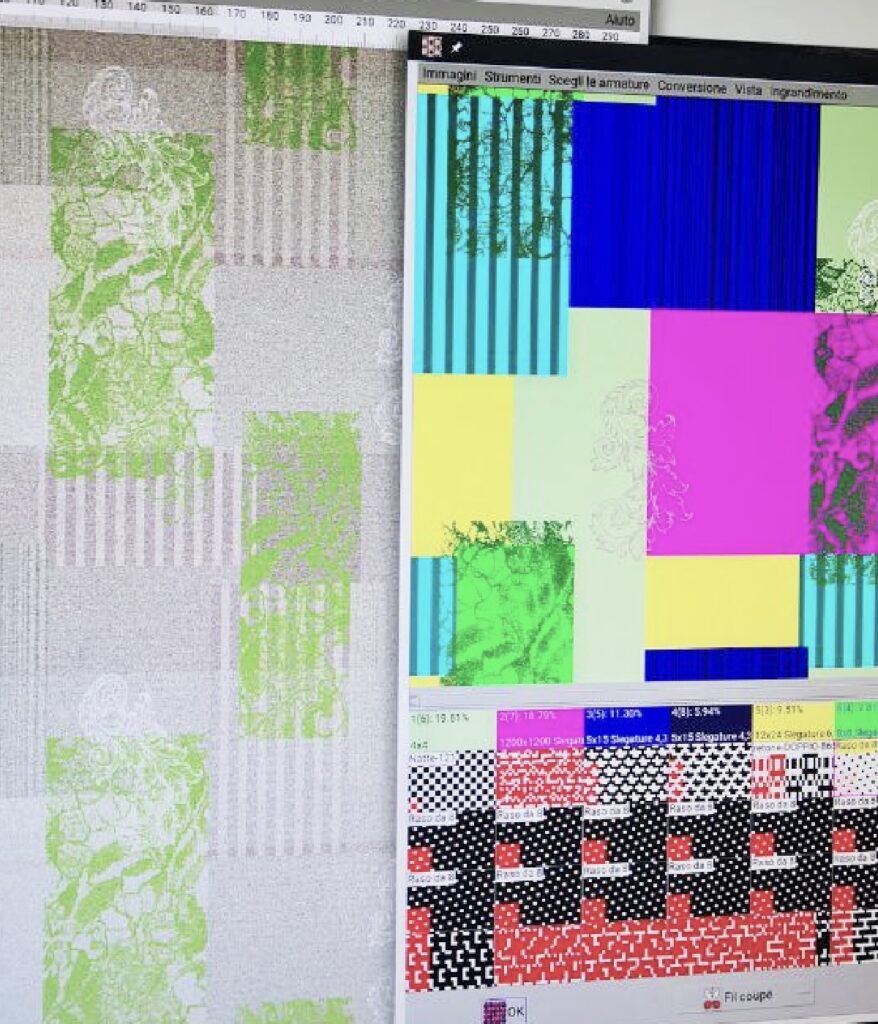

A distinguishing aspect of our organization is that an important part of its manufacturing is developed in close collaboration with its customers’ designers and style offices. The combination of our prototypes and qualities with their ideas and feedback results in the production of custom collections.

As a result, one-sixth of our personnel is always dedicated to researching, planning, and designing new goods, both for home textiles and clothes and accessories.

The experience and pleasure of creating and producing are enhanced by the most advanced and cutting-edge production and design technology, as well as ongoing research and innovation in terms of application programs.

Since 2019, DANZO Srl has been employing a new, unique, and customized software that has replaced pre-existing applications; this application communicates closely with textile CAD, effectively combining the two platforms.

This was made possible by Carlo Antonio’s continuous work with his trusted programmers, who have a background and enthusiasm for electronics and IT as well as textiles.

The Danzo family’s will, passion, and conviction provide the resources required for the system’s ongoing innovation.

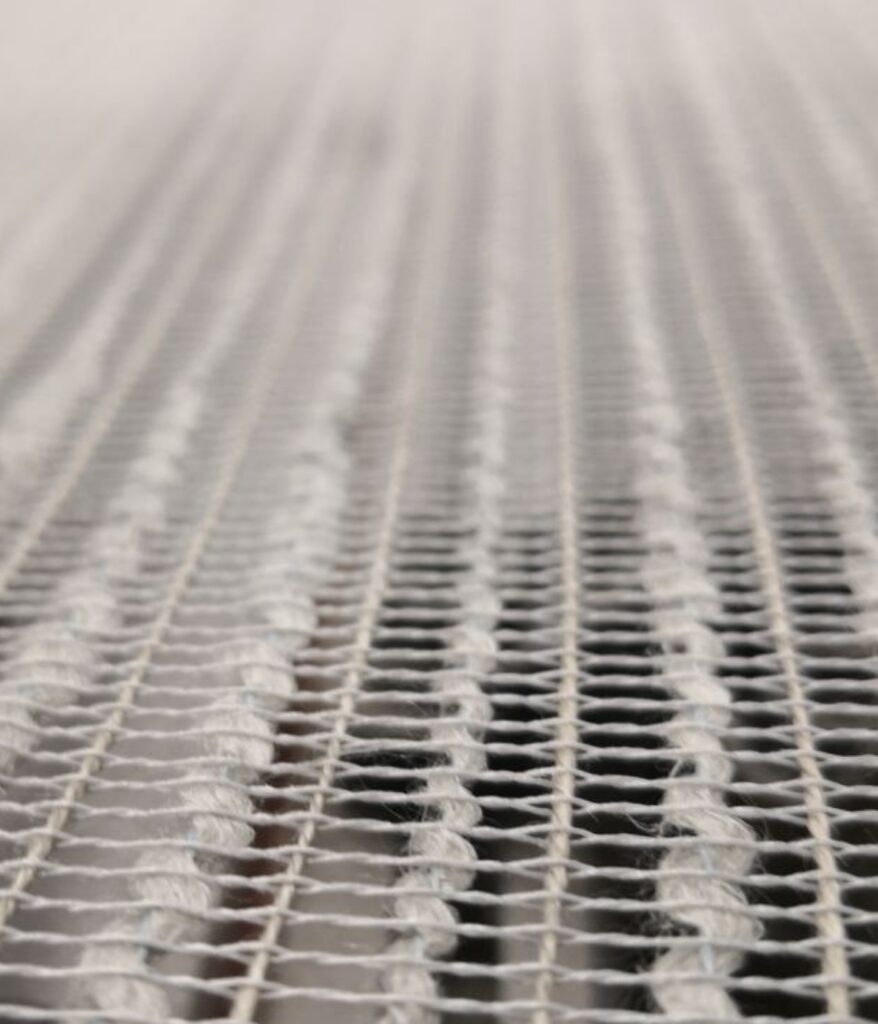

The weaving department

DANZO Srl has a modern and sophisticated weaving department with approximately seventy different assorted single and double height looms (dobby, jacquard, positive rapier, leno, double beams, etc…) that are fully equipped, in addition to raw fabric control, finished fabric control, and packaging control departments.

All of this ensures that we can provide our customers with optimum reliability and competitiveness from high technical and stylistic content or large-scale production.

During the two-year period 2021-2022, 8 latest generation double-height looms and a fully automated warehouse with 80 beams on four levels were installed, while the roofing of the entire building was replaced and further insulated with new materials to reduce heat losses, and 600 photovoltaic panels were installed to ensure the company’s energy autonomy.

Furthermore, a focus on educating collaborators at all levels ensures a sufficient response to the increased demand for variety, efficiency, and cost-effectiveness.

A UNI EN ISO 9001: 2015 certified quality system continuously monitors the entire workflow, from research to order delivery.